Fast-moving consumer goods (FMCG) live up to their name: short innovation cycles, frequent promotions, seasonal changes and tight retail deadlines. Packaging teams sit in the middle of this complexity – and are often still working with Excel, email threads and scattered PDFs.

Most discussions around digital packaging management currently focus on compliance with PPWR, EUDR and ESG. For good reason. But for many FMCG manufacturers, the immediate question is different:

How much time, rework and risk could we eliminate if our packaging management was actually automated?

This article looks at packaging management automation not only as a compliance tool, but as an operational efficiency lever – and outlines five tangible benefits for FMCG manufacturers.

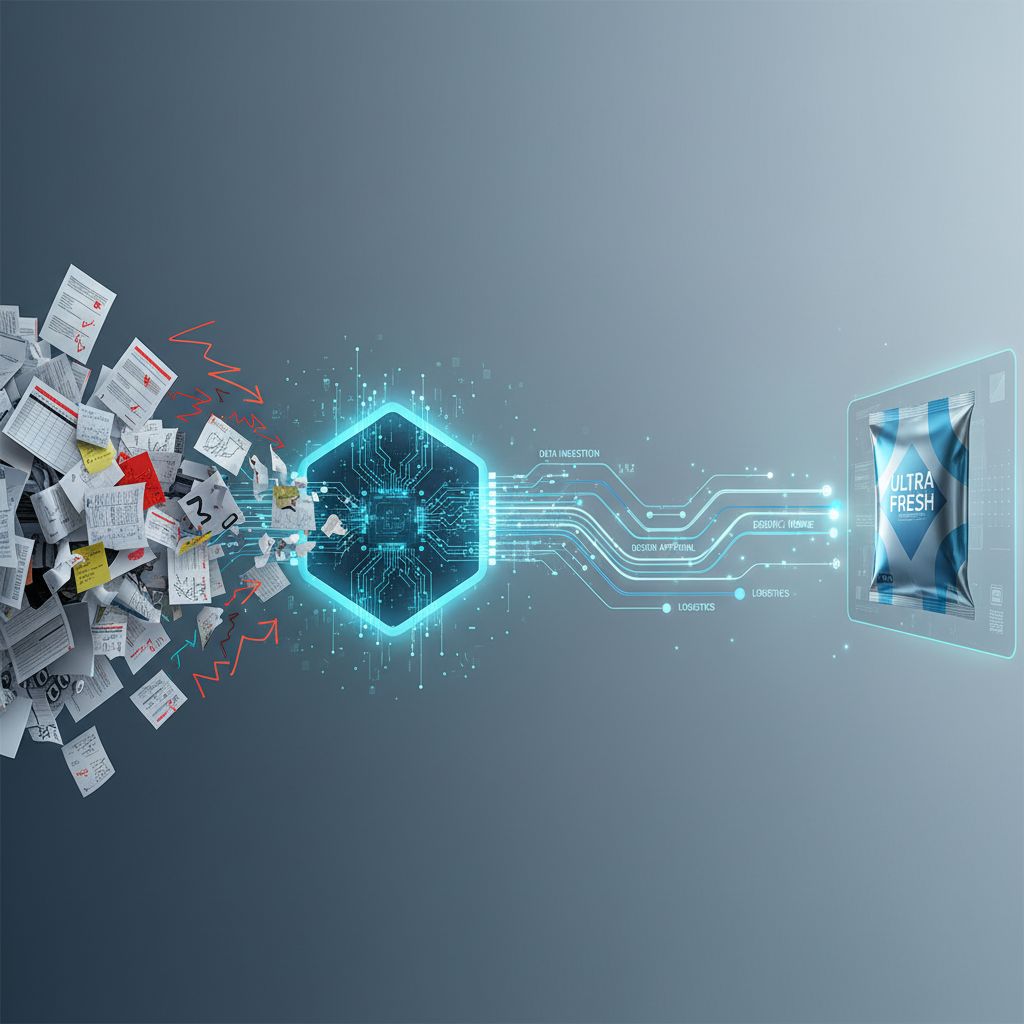

From manual packaging management to automated workflows

Typical FMCG packaging processes still look like this:

- Specifications are stored in different formats and versions (PDFs, supplier templates, ERP exports).

- Updates are exchanged via email; no one is sure which spreadsheet is the latest.

- Data for tenders, cost analyses or sustainability reporting has to be collected manually.

- Regulatory checks are done ad hoc with checklists and individual expertise.

This manual setup worked when portfolios were smaller and regulation was lighter. With 1,000+ packaging items, multi-country distribution and PPWR deadlines approaching, it has become a structural risk.

Packaging automation software addresses this by:

- Digitising and standardising all packaging specifications in a central database.

- Automating workflows such as approvals, supplier data collection and change requests.

- Running rules-based and AI-supported checks in the background (e.g. PPWR conformity, recyclability data completeness).

- Enabling real-time reporting for purchasing, sustainability and quality teams.

For FMCG manufacturers, the benefits go far beyond “being digital”. They directly impact speed, error rates and cost.

Benefit 1: Significant time savings in daily operations

For Heads of Packaging and Procurement Managers, the most visible gain from automated packaging management is time.

Where time is lost today

- Searching for the right version of a specification across shared drives and emails.

- Copy-pasting data from supplier PDFs into Excel for analysis.

- Chasing missing information and certificates from suppliers.

- Manually preparing data for tenders, price comparisons or audits.

Even in a mid-sized FMCG organisation, this can easily consume dozens of working hours per week across packaging, procurement, quality and sustainability.

How automation changes this

With a central, digital packaging database and automated workflows:

- Specifications are digitised once and then reused across teams and use cases.

- Data extraction from supplier documents is AI-supported and validated instead of manually retyped.

- Supplier requests and follow-ups are triggered and tracked automatically.

- Tenders can be pre-filled with existing, standardised specification data instead of rebuilt from scratch.

Packa customers typically report up to 70% faster tenders once packaging data is fully digitised and standardised, and multi-hour weekly searches for “the right spec” simply disappear.

For FMCG manufacturers operating on tight launch and promotion calendars, this time saving translates directly into more launches delivered on time and less firefighting.

Benefit 2: Fewer errors and production issues

Manual packaging management is inherently error-prone. Small inconsistencies quickly lead to costly consequences.

Typical error sources

- Outdated specifications being sent to converters or co-packers.

- Inconsistent data between packaging, quality and procurement systems.

- Missing or expired certificates that are only noticed during audits.

- Incorrect or incomplete regulatory or sustainability data added last-minute.

The impact ranges from reprints and scrapped packaging stocks to delayed listings, complaints and even product recalls.

What packaging automation software changes

Automated packaging management creates a single source of truth:

- All teams work on the same, validated specification set.

- Changes follow defined workflows with approvals and version control.

- Mandatory fields (e.g. recyclability parameters, material composition, certification dates) can be enforced.

- Systematic checks flag missing data or inconsistent values before they reach production.

This drastically reduces:

- The risk of wrong versions being used in artwork or purchasing.

- The likelihood of non-compliant packaging reaching the market unnoticed.

- The volume of manual corrections and emergency change requests.

For FMCG manufacturers with high SKU complexity, even a modest reduction in error rate can mean hundreds of thousands of euros saved annually – not to mention the reduction in stress and firefighting for packaging and quality teams.

Benefit 3: Faster, more data-driven packaging purchasing

In FMCG, packaging is a major cost block – but many organisations still lack a clear, consolidated view on prices, specifications and suppliers across categories and plants.

The limitations of manual purchasing analysis

- Price benchmarks are often done on a case-by-case basis, with limited transparency.

- Cross-supplier comparisons for similar specs are time-consuming.

- Opportunities for harmonisation (e.g. reducing the number of formats, materials or suppliers) are hard to identify.

How automated packaging management supports purchasing

A digital packaging platform such as Packa aggregates all relevant data centrally and enables:

- Real-time price analytics and supplier benchmarking across the entire packaging portfolio.

- Identification of harmonisation potential (e.g. same dimension, different suppliers; similar materials at different price points).

- Standardisation of specifications to increase volumes and improve negotiation positions.

Packa’s analytics have shown that FMCG manufacturers can unlock 15–40% savings in packaging costs by combining portfolio harmonisation with data-driven supplier benchmarking.

This is only possible when specifications, prices and supplier information are consistently structured and accessible – a direct result of packaging management automation.

Benefit 4: Seamless collaboration across packaging, procurement, quality and sustainability

In most FMCG organisations, packaging touches multiple functions:

- Packaging development defines structure, materials and formats.

- Procurement manages suppliers, contracts and prices.

- Quality ensures food safety, stability and certification.

- Sustainability/ESG teams need detailed data for reporting and target tracking.

Without a central platform, collaboration relies on email, meetings and manually updated spreadsheets – slowing down decisions and increasing the risk of misalignment.

How a central packaging platform improves collaboration

Packaging automation software provides:

- One shared, up-to-date repository for all packaging specifications, documents and sustainability data.

- Role-based access so each function sees the relevant data while working from the same base.

- Transparent workflows for approvals, change requests and releases.

- Traceability of who changed what and when – essential for audits and internal accountability.

FMCG manufacturers benefit from:

- Shorter time-to-decision for new packaging concepts and supplier changes.

- Fewer handover errors and misunderstandings between departments.

- Better alignment between cost, quality, sustainability and compliance objectives.

In practice, this often means that a Head of Packaging can coordinate complex projects (e.g. material changes for PPWR readiness) across functions without building manual project trackers – because the platform becomes the project backbone.

Benefit 5: Built-in compliance and sustainability reporting instead of manual scrambling

While this article focuses on efficiency, regulation is not going away. For FMCG manufacturers, PPWR, EUDR and ESG/CSRD requirements mean:

- More granular data on materials, recyclability and recycled content.

- Stricter documentation and audit readiness.

- Increasing demand from retailers and brand owners for proof of compliance and sustainability.

The cost of manual compliance processes

If packaging data is scattered, every new requirement triggers:

- A fresh round of data collection from suppliers.

- Manual consolidation of spreadsheets.

- One-off calculations and reports that need to be rebuilt for the next audit or regulation.

This is highly resource-intensive and difficult to scale.

Compliance as a by-product of automated packaging management

By contrast, a platform-first approach like Packa’s allows FMCG manufacturers to:

- Capture all relevant data points for PPWR, EUDR and ESG once, in a structured way.

- Run automated regulatory checks against current rules and thresholds.

- Generate audit-ready reports and documentation on demand.

- Use integrated sustainability analytics (e.g. CO₂ footprint, recyclability scores) for decision-making, not just reporting.

The key efficiency advantage: compliance and sustainability outputs become a by-product of well-structured, automated packaging management – not a separate, manual project every time regulation changes.

What FMCG leaders should do next

For decision-makers in FMCG packaging, procurement, quality and sustainability, the question is no longer whether packaging management needs to be digital and automated – but how quickly this can be implemented without disrupting operations.

Three pragmatic steps:

1. Assess your current packaging data landscape

- Map where specifications, documents and sustainability data currently live, how often they are updated and where errors or delays occur.

2. Prioritise high-impact use cases

- Typical starting points include: speeding up tenders, reducing specification errors in artwork and purchasing, and preparing for PPWR documentation requirements.

3. Select a specialised packaging management platform

Generic PLM or ERP extensions rarely cover the depth of packaging-specific needs. A dedicated solution like Packa offers:

- AI-powered digitisation of specifications.

- Centralised, cross-team collaboration.

- Automated regulatory checks and sustainability analytics.

- Real-time purchasing insights and supplier benchmarking.

By shifting the focus from “regulation as a burden” to automation as an efficiency engine, FMCG manufacturers can simultaneously:

- Reduce operational workload and error rates.

- Strengthen purchasing performance.

- Be better prepared for the next wave of EU packaging regulation.

The future of FMCG packaging management is not just compliant – it is digital, automated and data-driven.